The entire design process for a Pre Engineered steel building in Pakistan complete at a factory, and the building components are then deliver to the construction site in CKD (completely knock-down condition), where they are fix or joined and erect with the use of cranes.

Pre Engineered Steel Building structures with effective designs can be up to 30% lighter than traditional steel structures. Less steel requires for lighter weight, which could result in structural framework cost reductions.

Significant Pre-Engineered Steel Building Components

The Pre Engineered Steel Building in Pakistan primary components are group into four categories:

Basic Elements

Mainframe, column, and rafters are the Pre Engineered Steel Building in Pakistan basic structural elements.

Main Frame

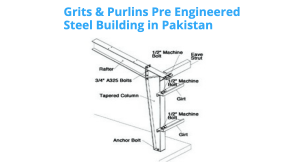

The stiff steel frames of the building make up the bulk of the primary framing. Tapered columns and tapered rafters make up the Pre Engineered Steel Building rigid frame. Flanges and webs must be joined together on one side by a continuous fillet weld.

Columns

They are primarily used to transfer vertical loads to the foundations. Columns in pre-engineered structures are constructed using I sections because they are more cost-effective than other types. The column’s width and breadth will continue to grow from the bottom to the top.

Rafters

A rafter is one of several sloped structural components (beams) used to support the roof deck and its accompanying loads. These members run from the ridge or hip to the wall plate, downslope perimeter, or eave.

Supporting Elements

Secondary structural components including purlins, grits, and eave struts support walls and roof panels.

Grits and Purlins

The roof supports by purlins. The walls are by grits, and the roof meets the sidewall at the eaves with struts. Cold-formed “Z” sections with stiffen flanges must use for purlins and girts.

Eave Struts

Eave struts must be “C” sections with uneven flanges. It is 200 mm deep and have top and bottom flanges that are each 104 mm broad and parallel to the roof slope. There is a 24 mm stiffener lip on each flange.

Bracings

A key component that guarantees the stability of the building against longitudinal pressures like wind, cranes, and earthquakes is cable bracing. The side walls and roof must both have diagonal bracing.

Cladding or Sheeting

The sheets used in the construction of pre-engineered structures are either base metal of cold-rolled steel with a high tensile yield stress of 550 MPA or aluminum with a hot dip metallic coating of Galvalume sheet, both of which comply with ASTM B 209M.

Basic Accessories

Bolts, turbo ventilators, skylights, lovers, doors, windows, roof curbs, and fasteners are examples of non-structural construction components that make up the accessories of a pre-engineered steel building.

Our Pre Engineered Steel Building Features

Our steel structures are incredibly cost-effective and significantly speed up project completion. It is essential to have open space with a maximum clear span to enable an effective layout, whether the project is industrial or not.

We offer this capability and enhance the project’s value by:

- Greater clear Spans, Faster, More Economical Construction, and Flexibility for Future Expansion or Modification

- A building that is both environmentally and energy-efficient

- Add a modern aesthetic touch to the project’s overall design.

- Lower Cost of Maintenance

Leave A Comment